Durable products that help you get the most out of your conveyor systems and pyro-process.

When business is booming for the construction industry, production lines at cement plants can’t move fast enough. At these times, keeping up with your customers' demands is a welcome challenge. For you, that means nothing is more important than keeping material moving through the crushers, preheaters, clinker coolers and kilns, all the way to the storage silos as efficiently as possible.

At Martin Engineering, we manufacture durable products that efficiently transport bulk materials like limestone, gypsum, clinker and coal for customers located throughout the world. So we know how your bulk materials handling processes work, the types of problems you encounter every day and, most important, how to solve them.

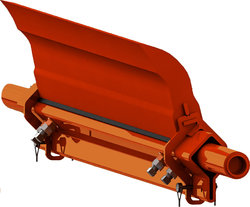

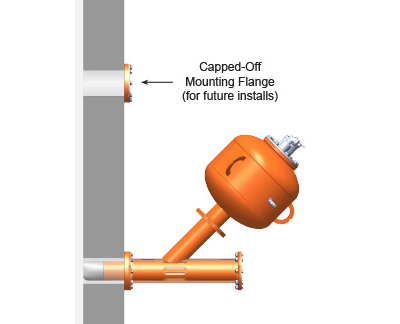

Air Cannons - Prepare Now & Save Later

If you know you’ll need to install air cannon nozzles down the road, take advantage of scheduled downtime by installing new flanges now. Once they’re installed, they can easily be sealed until you’re ready to upgrade to new equipment. Plus, we’ll supply the new flanges and installation kit at no cost!

Get Your Free Installation Kits NowAir Cannons Drastically Reduce Unscheduled Outages At Cement Plant

Air Cannons Improve Material Flow While Optimizing Limited Space

Air Cannons Eliminate Need For Water Blasting

Flow Aid Solutions Reduce Production Outages At Cement Plant

Air Cannons Reduce Need For Manual Cleaning

MartinPLUS® Silo Cleaning Corrects Ratholing In Cement Vessel

Belt Cleaner Minimizes Need For Difficult Manual Cleaning

Belt Cleaners Improve Safety and Efficiency At Cement Plant

Air Cannons Eliminate Blockages Caused By Sticky Iron Ore

Martin® Silo Cleaning and Air Cannons Prevent Limestone from Clogging and Shutting Down the Silo

Durability. Reliability. Efficiency.

In your business, when equipment failure causes an unexpected shutdown, the consequences can be disastrous. If the wrong piece of equipment breaks down – like the conveyor to the front-end grinder or the air cannons that keep material moving through the preheaters and kilns – the whole operation can go down. When fugitive material spills from the conveyor belt, it can't be recovered and re-used so that spillage equals lost profits. That’s why the equipment you count on every day has to be designed and engineered to work when it’s supposed to, and to be durable enough to last.

Currently, thousands of long-time Martin customers rely on our products because they work hard and they keep working for a long time. We want you to be as confident in our products as they are, and that’s why we back our equipment up with a 100% Money-Back Guarantee.

So whatever challenge you may be facing, we have most likely seen it, figured out the solution, and tested it to make sure that it works! And if you have a problem we’ve never seen, we love new challenges! Contact a Martin representative to find out how we can apply our decades of cement industry experience to solving your problems today!

- Keep downtime for maintenance and housekeeping to a minimum

- Move material more efficiently along conveyor systems

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Manage airborne dust and minimize the risk of explosion and inhalation

- Prevent material from spilling off of moving conveyor belts

- Eliminate the need for workers to enter confined spaces

- Reduce costs by minimizing waste and reducing energy consumption

- Deliver more product by maximizing overall throughput

- Eliminate excessive downtime for maintenance and cleanup

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back CopyMr. Blade® Service Includes FREE On-Site Delivery, FREE Blade Installation, FREE Mainframes and Tensioners.

Learn More About This Program