Boost your profits by increasing output and keeping costs down!

From the raw material fresh from the mine to the finished parts, complex transportation processes are used and there are many points along the way where obstructions can slow things down. As it’s transported, material can spill from mistracked conveyor systems or stick to the bottom of the belt, while poorly designed transfer points can allow fugitve dust to escape.

From the raw material fresh from the mine to the finished parts, complex transportation processes are used and there are many points along the way where obstructions can slow things down. As it’s transported, material can spill from mistracked conveyor systems or stick to the bottom of the belt, while poorly designed transfer points can allow fugitve dust to escape.

The metals industry is a challenging environment, and global competition forces companies to operate at the highest level of efficiency. That means operations managers are under constant pressure to safely increase throughput while reducing labor costs. Whether you're processing metals, such as gold, copper, molybdenum, iron ore or taconite, conveyor systems operating cleanly and safely provide the potential for significant increases in productivity.

At Martin Engineering, we’ve helped our customers in the metals industry by making sure they get the most out of the equipment they already have. We help them with belt cleaners that clean their conveyor belts at the head pulley, eliminating carryback. This reduces wear and tear on the equipment and minimizes product loss. We help them with products that eliminate dust problems, which improves efficiency while also eliminating the health and safety risks caused by fugitive dust. We also help them keep bulk materials moving smoothly through silos, hoppers and chutes with products like air cannons, industrial vibrators and engineered transfer point solutions.

Our products are designed and manufactured to be durable and get the job done, even in the most challenging environments, including extreme temperatures. From transfer points designed for extreme loading to belt cleaning systems engineered for high belt speeds, Martin has products designed specifically to perform under your most brutal conditions.

We guarantee our products 100%!

When your goal is to be as efficient as possible, the equipment you use absolutely has to work at all times! At Martin Engineering, we back all of our products and services with our 100% Money-Back Guarantee. If you’re not completely satisfied with the performance of any product, we will gladly refund your money no questions asked. We’ll even reinstall your old equipment.

Give us a call and talk to one of our professional engineers or technicians. We’ll take the time to listen and will probably have a few questions about your operation, the challenges you face and what you’ve already tried as a solution. There’s a very good chance that, no matter what’s giving you headaches, it’s something we’ve seen before. In fact, we’ve probably come up with a solution and tested it to make sure it works! And if not, we’re always up for a new challenge!

- Keep downtime for maintenance and belt cleaning to a minimum

- Move material more efficiently along conveyor systems

- Reduce spillage and equipment damage by keeping conveyor belts clean and aligned

- Manage airborne dust and minimize the risk of explosion and inhalation

- Prevent material from spilling off of moving conveyors

- Protect workers from extreme temperatures and moving equipment

- Deliver more product by maximizing overall throughput

- Eliminate excessive downtime for maintenance and housekeeping

- Reduce costs by minimizing waste and reducing energy consumption

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

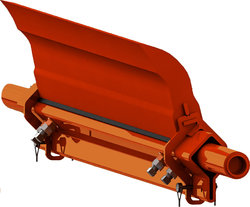

Efficiently Remove Carryback on Both Vulcanized and Mechanically Spliced Belts

The CleanScrape® Cleaner can last up to four times as long as traditional cleaners and can be used on belts with both mechanical and vulcanized splices. It lasts longer and cleans better, while using the lowest blade-to-belt pressure on the market. It is a revolutionary concept in belt cleaning technology that provides high performance with minimal wear and tear on belts.

See This Cleaner In Action and Understand the Difference Now

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!