Increase your productivity and profits in your foundry plant by eliminating unscheduled stoppages.

In a global economy, the market for metal and metal products is driven by manufacturing demand from around the world. If you’re in the business of producing metal parts – or the raw metals used to create them – both your customer and your competition can come from anywhere in the world. That means you have to be able to move materials through your process efficiently, whether it’s transporting raw ore from the railcar to the crusher to the furnace, or simply moving the sand used for making foundry molds.

Because these are linear processes that advance from station to station, a small, seemingly isolated problem can bring the whole foundry plant to a stop. For example, when carryback accumulates under the conveyor belt or spills onto the floor from a transfer point, the process shuts down for cleaning. If a belt starts to vibrate beyond acceptable tolerances and a cloud of dust starts to fill the plant, it’s both a health and safety risk and your plant stops running for maintenance and cleanup. And when the plant stops, so do revenues and profits.

At Martin Engineering, we got our start more than 70 years ago manufacturing industrial vibrators for smelters and foundries. Our professional technicians and engineers are experts at evaluating foundry plant operations and solving problems. We manufacture tough, durable products designed to keep conveyor systems running smoothly, efficiently and safely with zero or minimal unscheduled downtime. From the point where the raw material is unloaded from the ship or railcar, our products help you maximize the efficiency of the complex conveyor system that connects the crushers, boilers and reduction cells needed to turn chunks of ore into profits.

At Martin Engineering, we got our start more than 70 years ago manufacturing industrial vibrators for smelters and foundries. Our professional technicians and engineers are experts at evaluating foundry plant operations and solving problems. We manufacture tough, durable products designed to keep conveyor systems running smoothly, efficiently and safely with zero or minimal unscheduled downtime. From the point where the raw material is unloaded from the ship or railcar, our products help you maximize the efficiency of the complex conveyor system that connects the crushers, boilers and reduction cells needed to turn chunks of ore into profits.

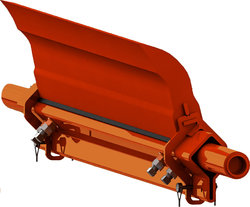

At foundries, one of your biggest concerns is managing all the sand required to make your molds, and because sand retains moisture, keeping the belts clean can be a challenge, so carryback is a common problem. Plus, many foundries operate in tight spaces, making it difficult to add equipment to your conveyor belt systems. Fortunately, we offer an extensive variety of belt cleaners designed to fit in small spaces while still thoroughly cleaning sand from the belts at the head pulley. This eliminates carryback and prevents accumulations of fugitive material, resulting in lower costs for housekeeping.

We also manufacture industrial vibrators that help you maintain quality by compacting the sand during the mold-fabrication process. Vibration also safely removes casts from molds and shakes the sand off without damaging the products. And our transfer point products are engineered to minimize the amount of fugitive material that spills off the belt. Plus, by minimizing fugitive material and airborne dust, you can eliminate the potential risk of worker injury or illness.

Backed by our unique “Problem Solved Guarantee."

We’re proud to say that most of our business comes from long-standing repeat customers. Our customers have 100% confidence that we will provide the right solution for their business every time. That said, if you’re considering a Martin product for the first time, we want you to have the same level of confidence our existing customers have before you buy. That’s why we back our products with our 100% Money-Back Guarantee. We call it the “Problem Solved Guarantee” because, if you’re not happy with any of our products, we’ll gladly refund your money. Problem solved!

We’re proud to say that most of our business comes from long-standing repeat customers. Our customers have 100% confidence that we will provide the right solution for their business every time. That said, if you’re considering a Martin product for the first time, we want you to have the same level of confidence our existing customers have before you buy. That’s why we back our products with our 100% Money-Back Guarantee. We call it the “Problem Solved Guarantee” because, if you’re not happy with any of our products, we’ll gladly refund your money. Problem solved!

Our professional engineers and technicians enjoy talking shop, so give us a call and let’s go over your plant operations, your challenges and how we can solve them. We have many customers in the steel production, smelting and foundry industries so, whatever your specific problem is, we’ve most likely seen it. And if we’ve seen it, we’ve solved it. Because that’s what we do every single day!

- Keep downtime for conveyor belt maintenance and housekeeping to a minimum

- Move material more efficiently along conveyor systems

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Prevent material from spilling off of moving conveyors

- Manage airborne dust and minimize the risk of explosion and inhalation

- Protect workers from extreme temperatures and moving equipment

- Deliver more product by maximizing overall throughput

- Eliminate excessive downtime for maintenance and cleanup

- Reduce costs by minimizing waste and reducing energy consumption

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Our Replacement Blades Have the Lowest Cost of Ownership of ANY Blades on the Market

When you need replacement blades for your belt cleaners, why settle for anything less than the longest-lasting, most-effective cleaners in the industry, when they are competitively priced and all backed by multiple guarantees?

You’ll Find The Proof You Need To Compare Right Here